Home : SMR : SMART Technology : Design

Design

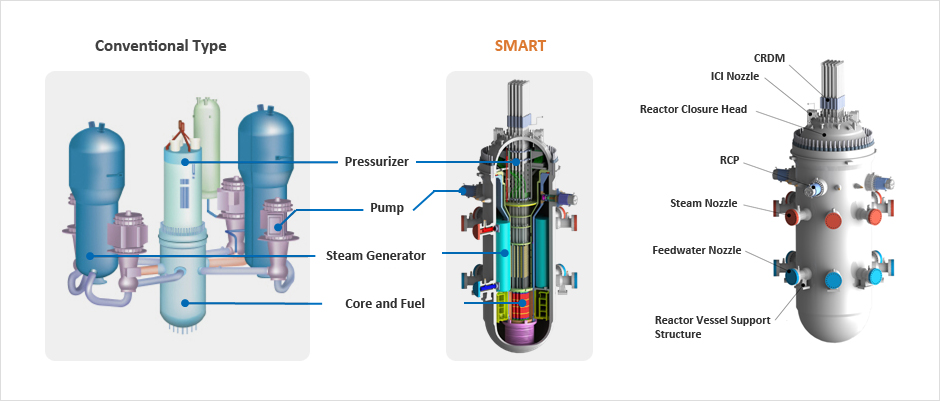

SMART is an integral-type small reactor containing major components such as pressurizer, steam generators, and reactor coolant pumps in a single reactor pressure vessel. This integrated arrangement of the reactor vessel assembly enables the large bore pipe connections to be removed, resulting in an inherent elimination of large break loss of coolant accidents (LB-LOCAs).

Eight once-through steam generators consist of helically coiled tubes to produce 30℃ superheated steam under normal operating conditions. A small inventory of secondary side water at the steam generator reduces possibility of a post-trip recriticality during main steam line break accident. Four reactor coolant pumps with a canned motor, which has no pump seals, inherently prevent a loss of coolant associated with a pump seal failure. Four channel control rod position indicators contribute to the simplification of the core protection system and to the enhancement of the system reliability. The in-vessel pressurizer is designed to control the system pressure at a nearly constant level over entire normal operation conditions.

Eight once-through steam generators consist of helically coiled tubes to produce 30℃ superheated steam under normal operating conditions. A small inventory of secondary side water at the steam generator reduces possibility of a post-trip recriticality during main steam line break accident. Four reactor coolant pumps with a canned motor, which has no pump seals, inherently prevent a loss of coolant associated with a pump seal failure. Four channel control rod position indicators contribute to the simplification of the core protection system and to the enhancement of the system reliability. The in-vessel pressurizer is designed to control the system pressure at a nearly constant level over entire normal operation conditions.

- About Us

- About us Location & Contact

- SMR

- SMART Technology - Development History - Design - Technology Validation - Standard Design Approval(SDA) - Implementation after Fukushima - Fields of SMART Application - SMART Key Data and Attractions SMART Projects - SMART Partnership with KSA - Commercialization with KSA

- Dismantling & Decommissioning

-

Management of radioactive and

hazardous waste Decommissioning of nuclear facilities Engineering & Consulting - Training Services

- Engineering & Consulting

-

International Employee

Deployment & Staffing - News